Basalt ore is too hard, which crusher is suitable for producing mechanism sand?

Basalt is a kind of high hardness ore, which is commonly used to build highways and high speed trains. However, due to its high hardness, it puts forward higher requirements for the selection of crusher. So, how to choose the right crusher in the process of producing sand and gravel?

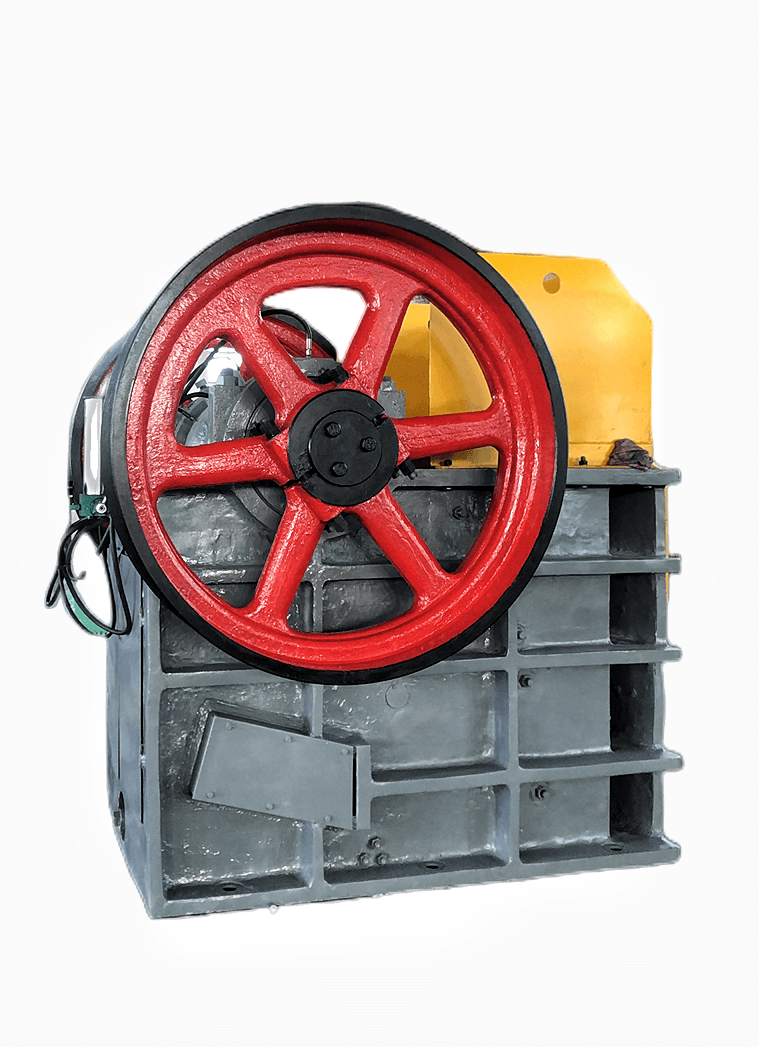

Jaw crushers are a common crusher model with strong crushing capacity and adaptability. Jawbreaker crushes the ore roughly through the movement of swinging jaw plate. For basalt, which is a high hardness ore, the jawbreaker can effectively crush it into smaller particles, laying the foundation for the subsequent crushing work.

The gyratory breaker can also crush the ore coarsely very well, except that the price is more expensive than the jawbreaker, but the output can be much higher than the jawbreaker. As the gyratory breaker has higher rotational speed and larger crushing force, it can cope well with the ore of basalt, which is of high hardness.

As a common hard rock crushing equipment, cone crusher can crush the ore well in medium and fine crushing. Therefore, it is more suitable in dealing with basalt, which is a high hardness ore.

If you need to produce 0-5mm fine sand, besides the crusher mentioned above, you can also add an

impact crusher for shaping to get the required fine sand.

For basalt, which is a high hardness ore, choosing the right crusher is crucial. Jaw, gyratory and cone

crushers are all highly recommended crushers for crushing hard rock. If you need to produce 0-5mm

fine sand, you also need to add an impact crusher for shaping. Choosing the right crusher equipment

not only improves production efficiency, but also ensures that the quality of crushed sand and gravel

meets the requirements.