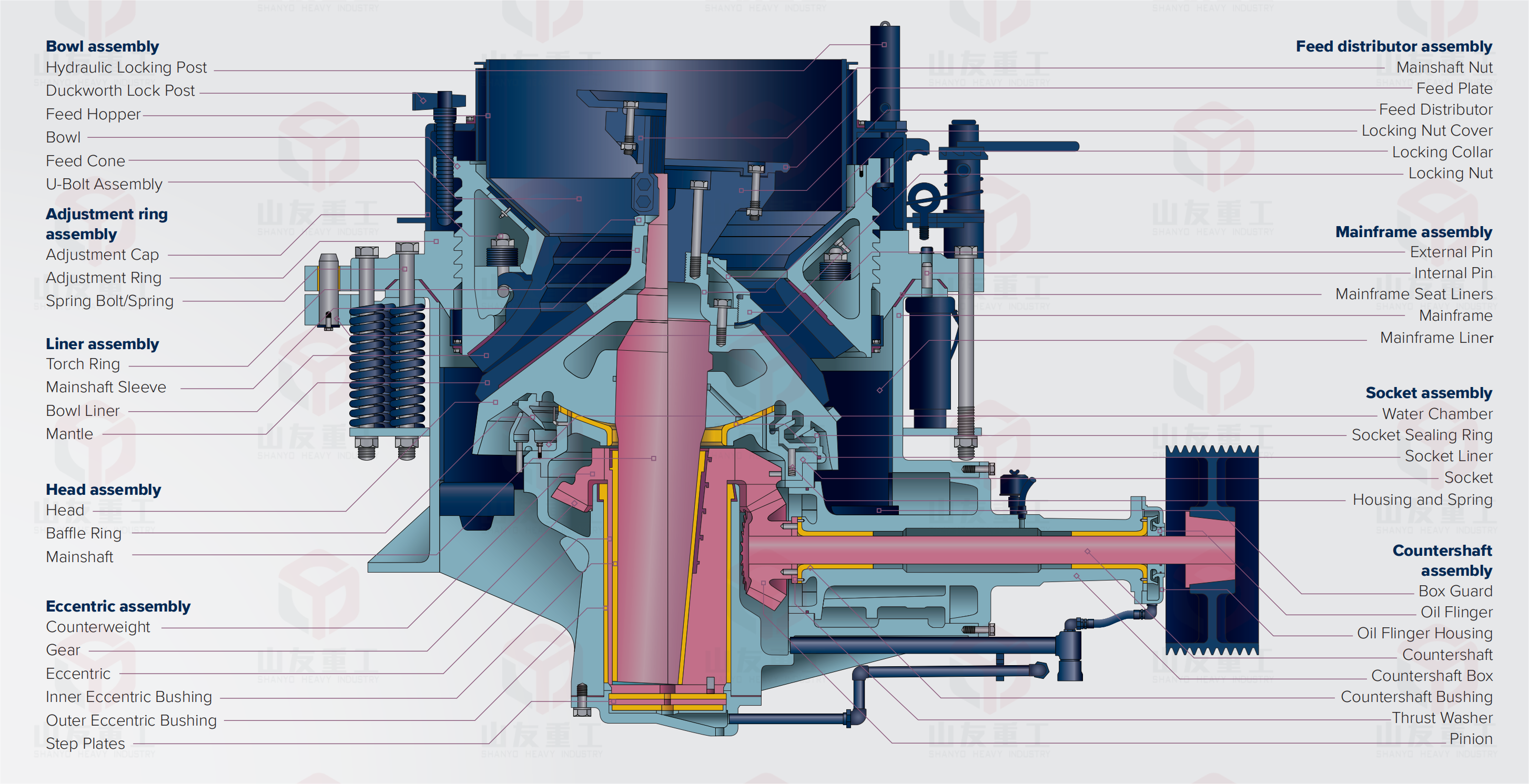

Product advantages of Symons cone crusher Feed Hopper

1、 Improved production

2 、More accurate product sizing

3 、Better wear metal utilization and lower discard weight

4 、Longer wear part life

5 、Lower overall operating costs

6、The advantages of the new cone are that the utility model is light in weight, small in size, large in eccentricity, and has a separate structure with the counterweight, and is convenient for disassembly, assembly, and maintenance.

Technical parameter of Symons cone crusher Feed Hopper

| Model | Part Number | Description |

| Symons 3ft | 1603-1121 | Feed hopper |

| Symons 4ft | 1063-1877 | Feed hopper |

| Symons 4ft | 1063-1898 | Feed hopper |

| Symons 4ft | 1063-1903 | Feed hopper |

| Symons 4 1/4ft | 1028-6361 | Feed hopper |

| Symons 5 1/2ft | 1063-4791 | Feed hopper |

| Symons 5 1/2ft | 1063-4826 | Feed hopper |

| Symons 5 1/2ft | 9439-8025 | Feed hopper |

| Symons 5 1/2ft | 9439-8026 | Feed hopper |

| Symons 5 1/2ft | 9439-8035 | Feed hopper |

| Symons 7ft | 1063-6471 | Feed hopper |

| Symons 7ft | 1063-7927 | Feed hopper |

| Symons 7ft | 1063-6375 | Feed hopper |

| Symons 7ft | 9439-9018 | Floating feed cone |

| Symons 7ft | 9439-9019 | Floating feed cone |

Quality control

1、High frequency infrared carbon &sulfur analyzer

2、Metallographic microscope

3、Machinery performance testing equipment

4、Hardness testing equipment

5、CST-22 Ultrasonic flow detector

6、Materials: High manganese or other materials as your requested.

7、 Use: Wear parts for crushers in the quarry, mining, construction and metallurgical industry fields, etc...

8、ISO9001 & CE certification.

9、Production quality testing: Hardness testing, metallographic structure, machinery performance testing and surface analysis etc...

10、Competitive products: Good quality with reasonable price.

11、Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

12、We can provide customized design according to our clients' requirement and also refine our products by our clients' feedback.

Ongoing Feedback Service

ShanYo is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude ShanYo makes it a point that past sales are just as important as the future. Because of this ShanYo will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.

Our goal is to provide minining equipment of excellent quality and reliability, in order to establish a reputation and relationship with our customers which will keep them customers for life.

We have a strict quality control system in place throughout the entire production process, so our products are all of the highest quality and reliability.

If you have a need for any mining equipment, or related spare parts, please feel free to contact us. We are dedicated to serving each of our customers to their complete satisfaction.

Certifications 🔗