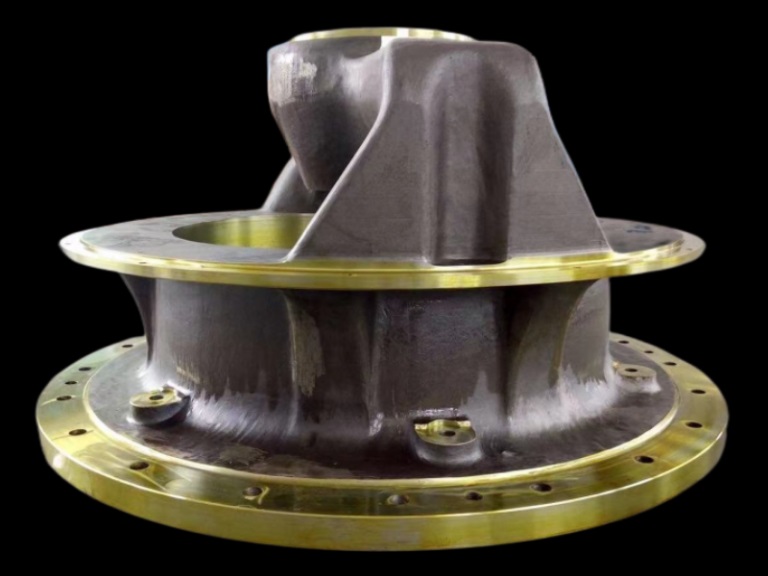

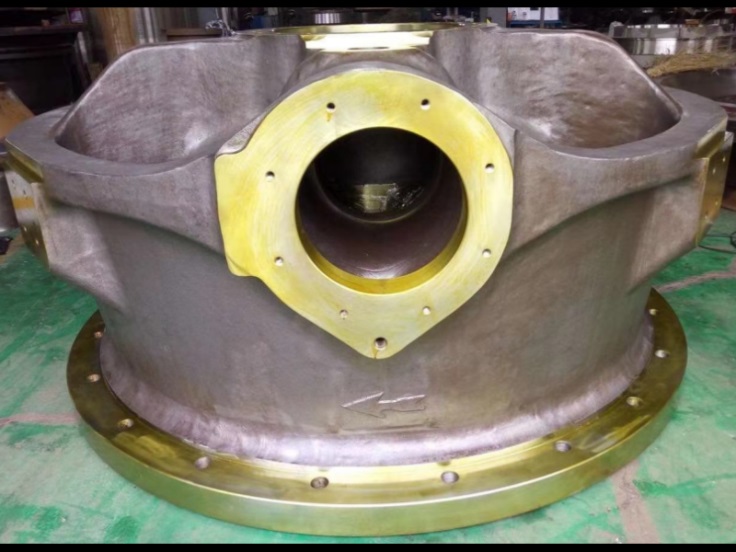

1. Sandvik Mainshaft sleeve is made of high quality materials with excellent strength and wear resistance.

2. The sleeve has low friction coefficient and good thermal conductivity, which can effectively reduce friction and heat generation.

3. The Sandvik Mainshaft sleeve is precisely machined and manufactured to ensure the precision of its dimensions and fit.

Send EmailMore2. The sleeve has low friction coefficient and good thermal conductivity, which can effectively reduce friction and heat generation.

3. The Sandvik Mainshaft sleeve is precisely machined and manufactured to ensure the precision of its dimensions and fit.