What is the best crusher for stone crushing and processing? How much does the stone breaking equipment cost?

Stone is stone by mechanical crushing, screening made of stone, as the basic construction, chemical industry, metallurgy, transportation and other fields of the main material, the demand continues to rise in the past few years. In the process of crushing and processing stone, choosing the right crusher is an important link. The right crusher can not only ensure the quality and efficiency of stone crushing, but also significantly reduce costs. So what is a good crusher for stone crushing and processing? How much does the stone crushing equipment cost? Here we will look at it.

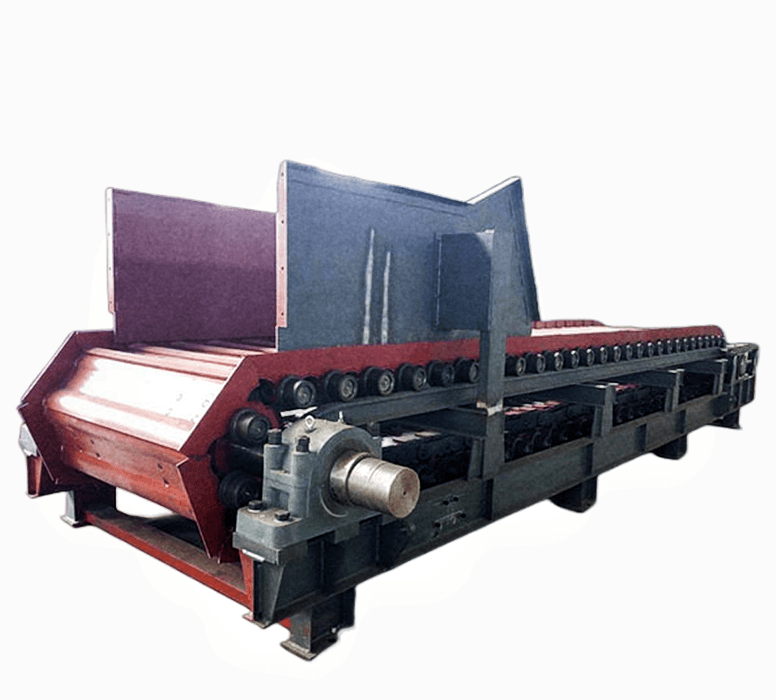

There are many common types of stone crusher for stone processing on the market, including jaw crusher, impact crusher, cone crusher, impact crusher and so on. Below is an introduction for you one by one.

Jaw Crusher

Jaw crusher is known for its powerful crushing force and crushing range. It is suitable for crushing hard rocks, ores and other materials. Its working principle is to crush materials through the squeezing force between two jaw plates. Due to its wide adaptability, jaw crusher is widely used in the forefront step of stone crushing processing, handling large materials and realizing preliminary crushing.

Impact Crusher

Impact crusher is mainly used for medium and fine crushing operation, suitable for materials below medium hardness. Its working principle is to utilize the high speed impact of the hammer head to crush the materials. With high crushing efficiency and stable performance, the impact crusher is suitable for fine crushing of materials in the middle and late stages of stone crushing.

Cone Crusher

Cone crusher is suitable for medium and fine crushing operation, applicable to materials below medium hardness. Its working principle is to utilize the crushing pressure of the crushing cone to crush the materials. Cone crusher has good product size distribution, suitable for crushed stone processing which requires better size distribution.

Impact Crusher

Impact crusher is mainly used for medium and fine crushing, suitable for crushing brittle materials. Its working principle is to utilize the high-speed rotating hammer head to crush the materials by impact and collision. Impact crusher is characterized by strong crushing capacity and high crushing efficiency, which is suitable for fine crushing operation in stone crushing processing.

For the above models of stone-breaking equipment, the price shows differentiation, affected by more factors, with the type of equipment, model selection, and now there are a lot of manufacturers on the market, the product is not the same in all aspects, usually in the hundreds of thousands of hundred thousand to hundreds of thousands of dollars or even millions of dollars, direct consultation with the crusher manufacturer is more accurate.

Shenyang Shanyou Heavy Industry belongs to the direct sales type manufacturers, equipment directly for everyone, more affordable, specific stone breaking equipment how much, welcome to online consultation to understand, and after-sales service do not have to worry about, if there is anything uneasy or want to understand, you can always go to Shenyang Shanyou plant site inspection visit.