What kind of stone is cone crusher suitable for crushing?

Cone crusher is widely used in stone crushing industry, which can crush large stones into small particles for subsequent processing or use. What kind of stone is cone crusher suitable for crushing? Let's explore it below.

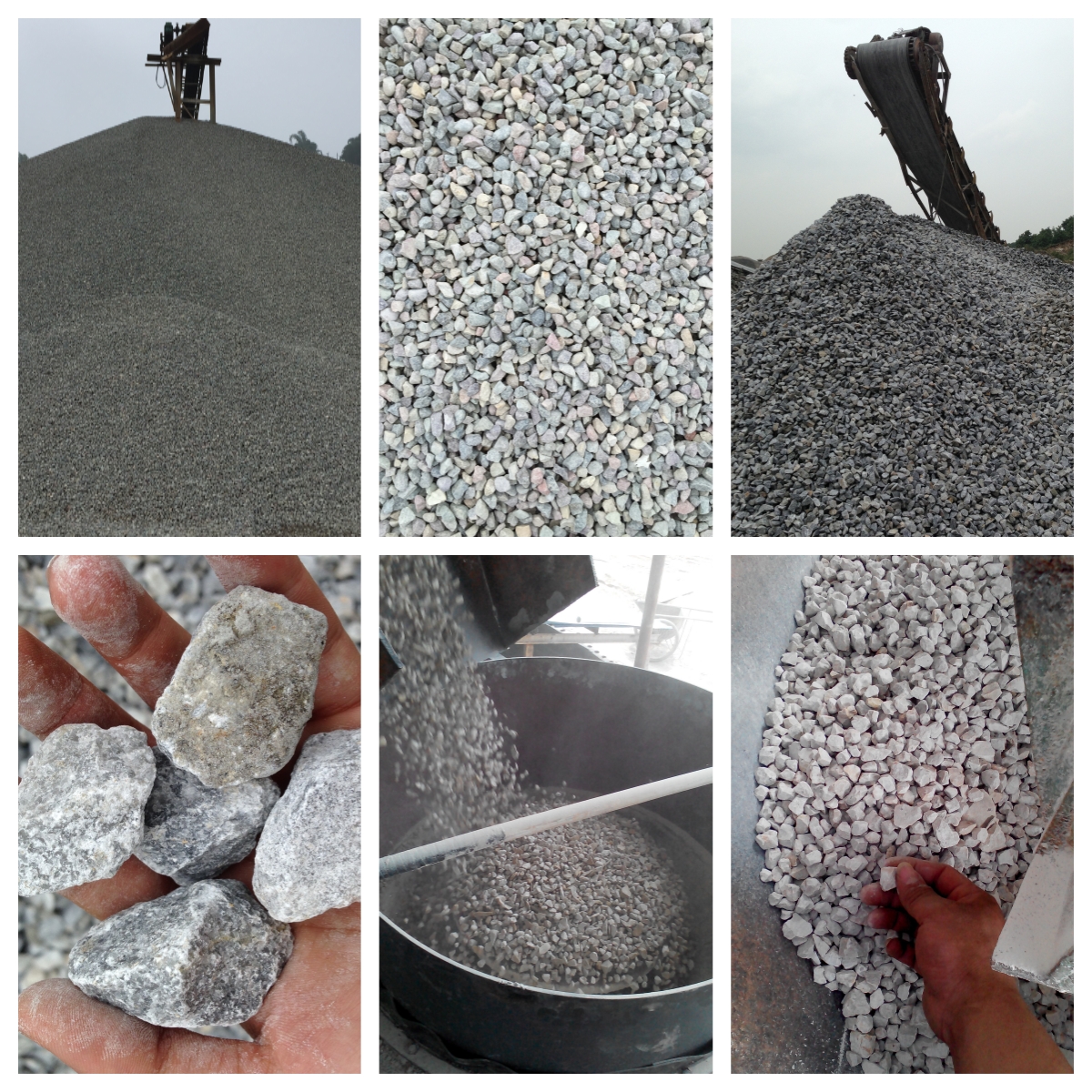

First of all, cone crusher can crush hardness stones. Whether it is softer limestone, granite, marble, or harder sandstone, basalt, cone crusher can adapt and complete the crushing task. This is due to the unique design and efficient crushing capacity of the cone breaker, which enables it to cope with stones of different hardness.

Secondly, cone crusher is suitable for stone with particle size. For some stones with larger particles, the cone crusher can crush them into medium-sized pieces through primary crushing; and for some stones with smaller particles, the cone crusher can crush them into finer particles through secondary crushing. In this way, it can meet the needs of different users for stone granularity.

In addition, the cone crusher is also suitable for different processes and equipment configurations. In some processes, the cone crusher can be used as the main crushing equipment to crush large stones into small particles; while in other processes, the cone crusher can be used as the auxiliary equipment, which can be used in conjunction with other crushing equipments to achieve a better crushing effect.

In addition, the cone crusher has the advantages of high efficiency, low energy consumption, easy maintenance and repair. It adopts advanced crushing principle and technology, which can realize high efficiency crushing and low energy consumption. At the same time, the cone crusher has a simple structure, durable, easy to maintain and repair, and can ensure long-term stable operation. These advantages make cone crusher one of the ideal equipment in stone crushing industry.

Different models and specifications of cone crusher will have different processing capacity, you need to choose the right model and specifications according to the actual demand.

Different hardness and particle size of the stone need to use different models and specifications of the cone crusher to crush.

Different processes and equipment configurations will have an impact on the processing capacity of the cone crusher, so you need to choose the right process and equipment configuration according to the actual situation.

Improper operation and maintenance will lead to cone crusher failure or efficiency decline, so you need to choose a cone crusher that is easy to operate and maintain.

When choosing a cone crusher, you need to consider its productivity and production costs. A cone crusher with high production efficiency can improve production efficiency and reduce production costs; while a cone crusher with low production costs can reduce operating costs and improve economic efficiency.