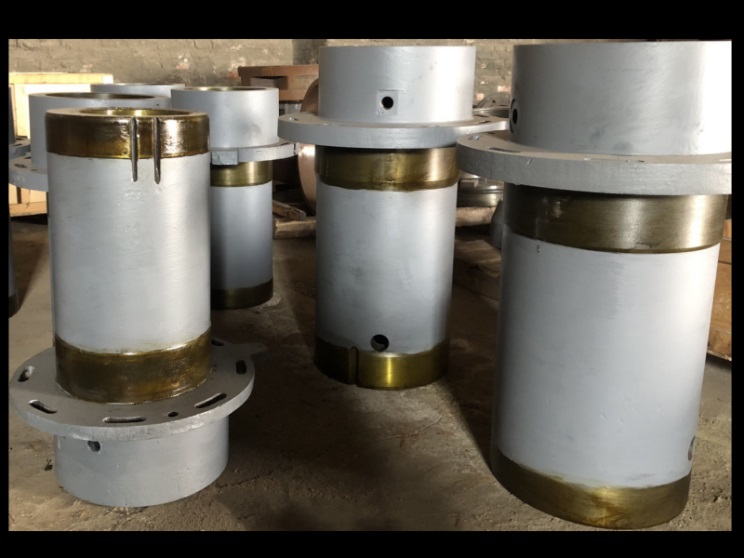

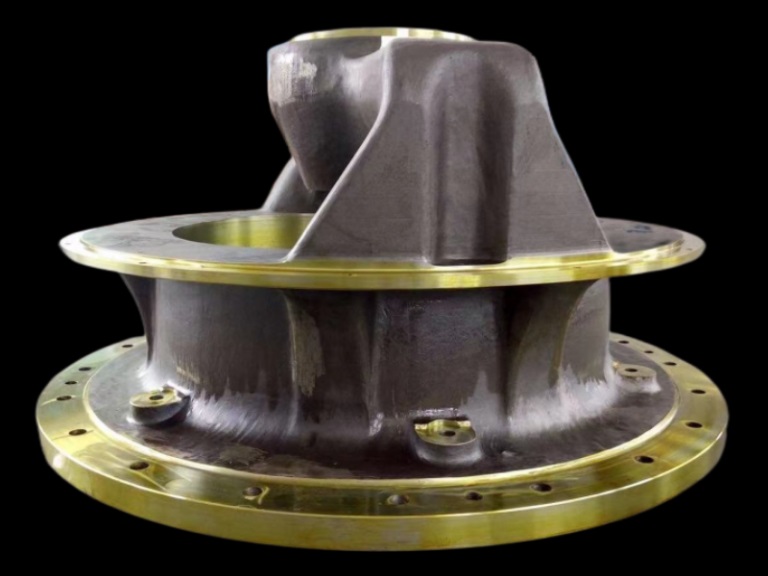

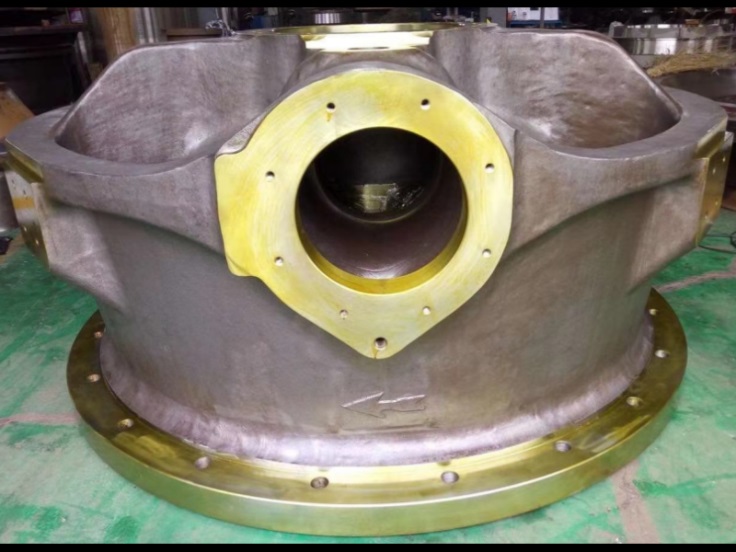

1. Sandvik Countershaft Box is made of high strength material, which can bear high load and impact force, and guarantee the stability and durability of the equipment.

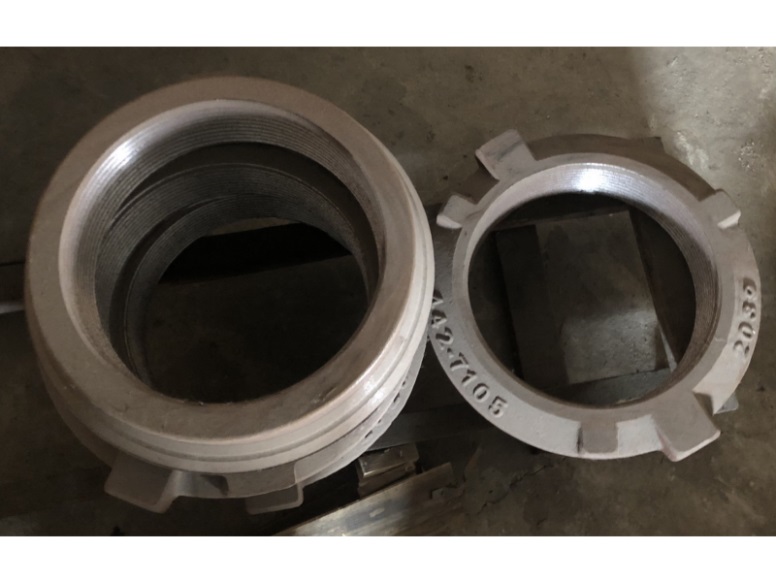

2. The Sandvik Countershaft Box is precisely machined to ensure accurate dimensions to ensure compatibility with other equipment and smooth operation.

3. The Sandvik Countershaft Box has an efficient sealing design that effectively prevents oil leakage and dust from entering the equipment and protects the normal operation of the equipment.

Send Email

More

2. The Sandvik Countershaft Box is precisely machined to ensure accurate dimensions to ensure compatibility with other equipment and smooth operation.

3. The Sandvik Countershaft Box has an efficient sealing design that effectively prevents oil leakage and dust from entering the equipment and protects the normal operation of the equipment.