Product advantages of Metso HP Cone Crusher

1、Metso HP Cone Crusher release hydraulic cylinder through two-way iron passing can easily let iron block or unbreakable object pass through the crushing chamber.

2、HP300 crusher, has several significant advantages, which are mainly reflected in the

following aspects.

3、High efficiency and product quality: HP400 crusher achieves higher crushing efficiency

and excellent final product shape through higher stroke, higher pivot point, higher crushing force and

higher power.

4、Reduced downtime and easy maintenance: HP cone crusher features a double-acting hydraulic

iron discharge release cylinder that passes through jammed iron without stopping or damaging

internal components. Also, the advanced fastening system reduces the time required to replace

liners and eliminates the need for backing material, which is environmentally friendly.

5、 Automation and intelligence: HP crusher IC700 automation system ensures optimum operating

parameters for the crusher, monitoring oil flow and temperature to ensure that the crusher always

operates in ideal conditions, while the system is easy to use with built-in help screens and

troubleshooting options.

6、Design features and eco-efficiency: Design features of Metso HP Cone Crusher include higher stroke,

optimized head and crushing chamber, higher speeds, one-piece main frame, quick and easy access

to all major components from the top, easy-to-remove bowl liners, liners that require no backing

material, and a hydraulic iron removal feature.

7、Cost Effective and Eco-Friendly: With higher output capacity and better chamber density than

similar sized crushers, the HP300 crusher is able to produce a finer end product with the same energy

consumption, and is equipped with the latest high efficiency motors, making it an efficient and

environmentally friendly crusher.

8、 Safety and User-Friendliness: Designed with operator safety and ease of maintenance in mind,

the HP400 crusher features quick and easy access to all major components from the top, double-acting

hydraulic cylinders to minimize downtime, and no backing material to make it more environmentally

friendly.

9、Market Leadership: With a wide range of customer applications worldwide, HP crushers maintain theirposition as market leaders and are well known for their reliability and performance in the aggregates

and mining industries.

10、Optimized performance: HP cone crusher is known for its unique combination of crushing speed,

throw, crushing force and chamber design, a combination that provides higher capacity and a better

quality end product in all secondary, tertiary and quaternary applications.

11、Continuous Innovation: Metso HP Cone Crusher is constantly innovating and continues to push the industry

standard through new technology development and feature upgrades, and the HP Series crushers

embody this spirit of innovation.

These benefits make the HP crusher a high-performance choice for the aggregates

and mining industries.

Technical parameter of Metso HP Cone Crusher

| Model | Ccvity | Standard | Short head | ||||

Min setting A' (mm) | Feed opening B2 (mm) | Min C.S.S.C3 (mm) | Min setting A' (mm) | Feed opening B2 (mm) | Min C.S.S.C3 (mm) | ||

| HP100 | EF | 20 | 50 | 6 | |||

| F | 50 | 100 | 9 | ||||

| M | 70 | 97 | 9 | ||||

| C | 100 | 124 | 13 | ||||

| EC | 150 | 176 | 21 | ||||

| HP200 | F | 95 | 128 | 14 | 25 | 66 | 6 |

| M | 125 | 156 | 17 | 54 | 70 | 6 | |

| C | 185 | 208 | 19 | 76 | 114 | 10 | |

| HP300 | F | 107 | 148 | 13 | 25 | 72 | 6 |

| M | 150 | 190 | 16 | 53 | 100 | 8 | |

| C | 211 | 240 | 20 | 77 | 123 | 10 | |

| EC | 233 | 267 | 25 | ||||

| HP400 | F | 111 | 164 | 14 | 40 | 104 | 6 |

| M | 198 | 245 | 20 | 52 | 107 | 8 | |

| C | 252 | 292 | 25 | 92 | 143 | 10 | |

| EC | 299 | 333 | 30 | ||||

| HP500 | F | 133 | 182 | 16 | 40 | 105 | 8 |

| M | 204 | 246 | 20 | 57 | 116 | 10 | |

| C | 286 | 322 | 25 | 57 | 116 | 10 | |

| EC | 335 | 372 | 30 | ||||

| HP800 | F | 219 | 264 | 16 | 33 | 98 | 5 |

| M | 267 | 308 | 25 | 92 | 150 | 10 | |

| C | 297 | 340 | 30 | 155 | 210 | 13 | |

| EC | 353 | 375 | 23 | ||||

| Closed setting | HP100 | HP200 | HP300 | HP400 | HP500 | HP800 |

| 6mm(1/4'') | 45-55 | |||||

| 8mm(5/6'') | 50-60 | |||||

| 10mm(3/8'') | 55-70 | 90-120 | 115-140 | 140-175 | 175-220 | 260-335 |

| 13mm(1/2'') | 60-80 | 120-150 | 150-185 | 185-230 | 230-290 | 325-425 |

| 16mm(5/8'') | 70-90 | 140-180 | 180-220 | 225-280 | 280-350 | 385-500 |

| 19mm(3/4'') | 75-95 | 150-190 | 200-240 | 255-320 | 320-400 | 435-545 |

| 22mm(7/8'') | 80-100 | 160-200 | 220-260 | 275-345 | 345-430 | 470-600 |

| 25mm(1'') | 85-110 | 170-220 | 230-280 | 295-370 | 365-455 | 495-730 |

| 32mm(1 1/4'') | 100-140 | 190-235 | 250-320 | 325-430 | 405-535 | 545-800 |

| 28mm(1 1/2'') | 210-250 | 300-380 | 360-490 | 445-605 | 600-950 | |

| 45mm(1 3/4'') | 350-440 | 410-560 | 510-700 | 690-1050 | ||

| 51mm(2'') | 465-630 | 580-790 | 785-1200 |

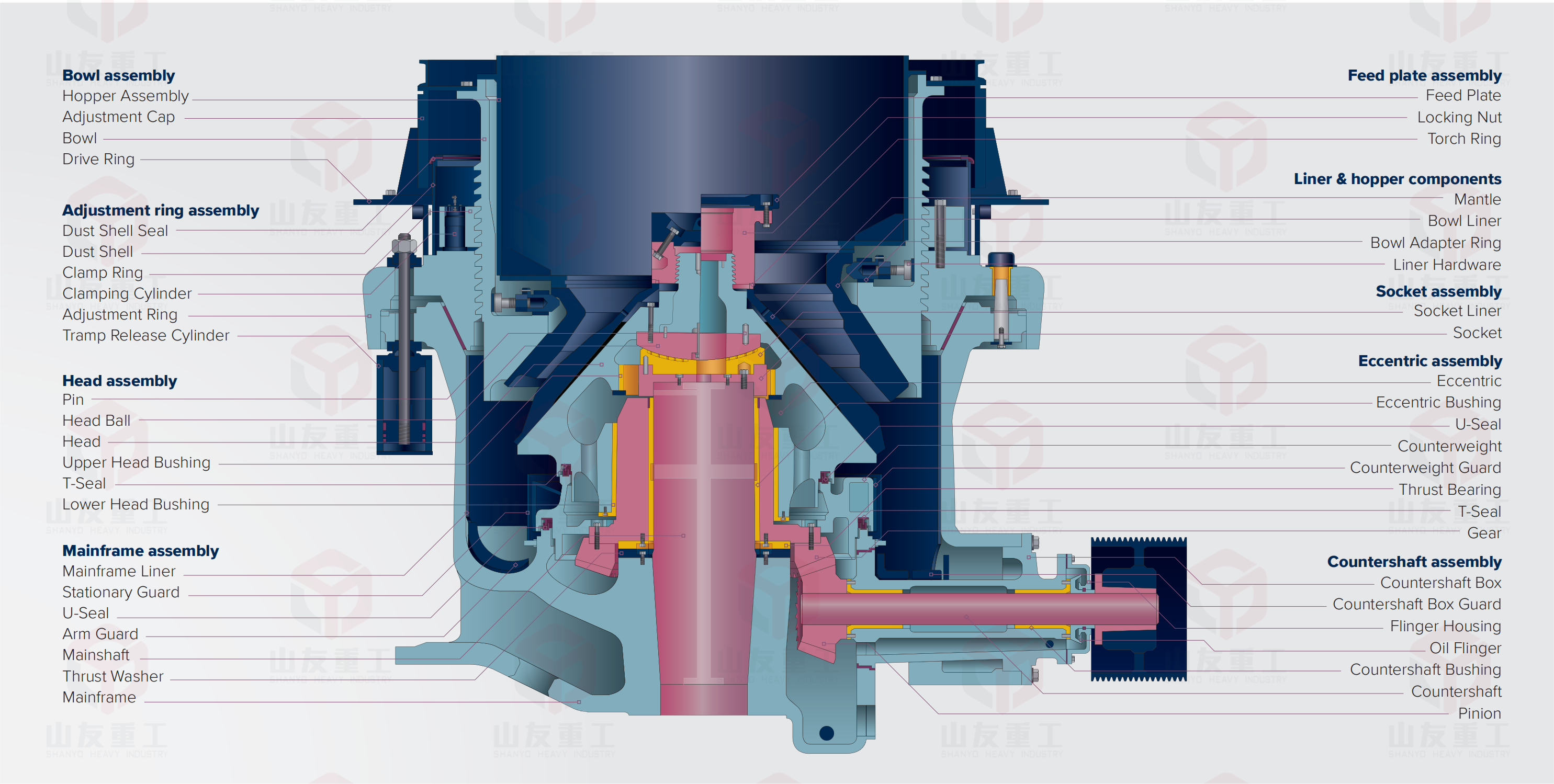

Parts of Metso HP Cone Crusher

Application of Metso HP Cone Crusher

HP300 crusher have a wide range of applications in many fields. Here is some

information about HP400 crusher applications:

1. HP cone crushers are one of the most popular cone crusher series in the world with over 10,000

machines sold worldwide. They are suitable for crushing a wide range of rocks and are widely used in

secondary, tertiary and quaternary crushing stages in aggregate production, quarrying and mining

applications.

2. HP crushers are known for their optimized combination of crushing speed, eccentricity and cavity

profile, which has proved revolutionary, offering higher capacity, better product quality and suitability

for a wider range of applications .

3. Metso HP Cone Crusher is known for its unique combination of crushing speed, throw, crushing

force and cavity design, a combination that has proven revolutionary in delivering higher capacity and

better quality end products. the HP300 crusher offers higher output capacity, higher crushing cavity density, and better reduction ratios in size category comparisons, producing a higher percentage of acceptable product for the same energy consumption. the HP4™ cone crusher is also known for its unique combination of crushing speed, throw, crushing force, and cavity design, a combination that has proven revolutionary in delivering higher capacity and better quality end product.

4.HP400 crusher are the newest addition to the Metso cone crusher portfolio. the MX Series cone

crushers utilize a revolutionary technology that combines a rotating bowl with a piston in one crusher.

Known for their low operating costs, high uptime and consistent high quality output, they are ideally

suited for secondary, tertiary and quaternary crushing stages in both hard and soft rock applications.

5. HP cone crusher is an effective crushing machine for secondary and tertiary crushing in aggregate

production, quarrying applications and mining operations.

These crushers are very popular in mining and aggregate production due to their high reliability, low

maintenance costs and high productivity. They can be adapted to different crushing requirements,

provide continuous compression to reduce material size through continuous compression between

fixed elements (bowl liners) and moving elements (cones), and allow crusher settings to be adjusted

according to material, feed size and capacity requirements.

Metso HP Cone Crusher is a key player in the mining industry and aggregate production

due to its outstanding performance and versatility. Below are some of the key features of the

HP300 crusher:

1. High output and high product quality: the HP400 crusher provides higher output and

better product shape through its unique crushing speed, eccentricity and cavity design.

2. Wide range of applications: HP cone crusher Suitable for crushing a wide range of materials from limestone to hard

iron ore, and for different production needs from small-scale aggregate plants to large-scale mining

operations.

3. Optimized performance: HP crusher by increasing the stroke, power and holding force, while improving the

crusher body design and weight to withstand greater forces, thus providing higher density and better

product shape.

4. Cost-effective and eco-friendly:Metso HP Cone Crusher offer higher output capacity, higher chamber

density, better crushing ratios and the ability to produce a higher percentage of specification-

compliant end products with the same energy consumption than comparable products.

5. Ease of maintenance and operation:HP300 crusher Designed with a focus on operator safety and ease of

maintenance, featuring quick and easy access to all major components from the top, as well as

double-acting hydraulic cylinders that significantly reduce downtime.

6. Reduced downtime: HP300 crusher the use of double acting hydraulic cylinders reduces downtime by allowing

the crusher to quickly clear the crushing chamber by clogging the iron and through a large sweeping

stroke.

7. crusher automation: HP400 crusher automation system further improves the operational efficiency

of the HP-Series crusher, which can be used to increase production by more than 10 percent.

8. Enhanced Dynamics: HP cone crusher offer higher throughput and better product shape through

enhanced dynamics.

9. Environmentally Friendly Design: HP crusher utilizes backingless manganese steel (dynamic and

static cone liners), whic

Certifications 🔗

FAQ 🔗

01.Are you a factory or a trading company?

Shenyang Shanyo Heavy Industry Machinery Manufacturing Co., Ltd., founded in 1996, is located in Shenyang, Liaoning Province, the old heavy industry base in northeast China. It is the first batch of factories producing and manufacturing mining machinery and equipment.

02.What products does your company mainly produce and also produce various parts?

Our company mainly produces various types of cone crusher, jaw crusher, rotary crusher, impact crusher, vibrating screen, feeder, ball mill and other products. At the same time, we also produce various equipment parts to provide customers with all-round services.

After purchasing the equipment, we will assign special after-sales service personnel free of charge to arrive at the site to guide customers in installation, commissioning, trial operation and on-site training of operators. The equipment is subject to three guarantees, and the warranty period is one year. After-sales service is the guarantee of long-term cooperation between the company and users. Our company has a professional after-sales service team with strong technical force. If the equipment fails during the warranty period, our company will arrange after-sales service personnel to arrive at the site as soon as possible to eliminate the fault and ensure the normal production of users.

We have not only advanced production equipment, such as CNC vertical lathe, Hangzhou crane, milling machine, boring machine and other equipment, but also 16 professional and technical personnel. At the same time, we also have advanced production technology. Shenyang Shanyou has been engaged in manufacturing mining machinery and equipment for 27 years. We are strict with ourselves to ensure that every product produced meets the factory requirements and customer requirements. We will carry out quality control on every detail, So as to produce high-quality machinery and equipment.

Ongoing Feedback Service 🔗

ShanYo is as concerned with not only the equipment we are selling tomorrow, but, with those out in the field already. With a customer first attitude ShanYo makes it a point that past sales are just as important as the future. Because of this ShanYo will periodically check in with current users to gather feedback and offer any practical feedback or necessary adjustments that will help obtain the upmost benefit to all our customers.